Photovoltaic Ground Mounting Systems

Reca RS

Durable substructures for Solar Parks.

Simple installation, durable, economical.

Manufacturer of Open-Field Mounting Systems for Photovoltaic Systems

Reca Solar is a manufacturer of mounting systems (PV substructures) for open-field photovoltaic systems. We plan, manufacture and – on request – install complete mounting system solutions in Germany, Austria, Poland and Switzerland.

The products offered are individually designed according to the investor’s requirements – taking into account snow and wind loads as well as local geological conditions. If necessary, we carry out test driving (pull-out test) to check the soil conditions.

The planning of the substructure of an open-field PV system is an important step to ensure the stability, safety and longevity of the system. We will be happy to advise you if you are not sure how to plan the substructure of your PV system.

We are specialized in the production of:

The Right Substructure for your Project

Reca RS substructures are made of high-quality materials that guarantee long-term durability and weather resistance. The mounting systems used are provided with a Magnelis® coating, which offers up to three times higher corrosion resistance than conventionally galvanized steel.

Discover the Advantages of Reca RS Mounting Systems

Easy Installation

The photovoltaic mounting systems we offer combine the highest quality with quick and uncomplicated installation.

Durable and Resistant

Through the use of the innovative Magnelis® coating, our photovoltaic mounting systems have 10 times higher corrosion resistance than conventional galvanized steel.

Economical

An economically optimized project ensures low costs and low material consumption, as well as high system reliability, leading to a lower price and higher return on investment over many years.

Find the Right Solution Now – We Will Advise You!

Are you planning an open-field PV system or would you like to know which substructure is the best fit?

We advise you on RECA open-field substructures. Together we will find the optimal RECA system for your project.

Our Offer – PV Ground Mounting Systems

Preliminary Planning / Concept

Whether and on which areas a solar park can be built at your location is the responsibility of the competent building authority and takes place within the framework of the land-use plan. Project-related layouts and material-optimized constructions guarantee the load-bearing capacity and reduce costs for every system size.

Planning

As a partner specialized in open-field photovoltaic systems, we support you in the planning and with the building application – taking into account the local conditions, the solar radiation, the shading and the possible number of photovoltaic modules.

Test Driving

First, we carry out test driving with our own hydraulic rammers. After clarification of the soil conditions, the support profiles are driven into the ground – usually at a depth of 1.5 to 2.0 m (project-specific).

Statics

RECA RS substructures are statically dimensioned and delivered with verifiable statics for open-field photovoltaic systems. The construction withstands wind and snow loads as well as gravity and ensures the safety and stability of the solar modules.

Construction

Our experienced installers build solar parks quickly: Depending on the soil type, we use rammed, screw or concrete foundations, followed by the steel construction. After the module installation, we take over the DC cabling and the connection to the inverters. The AC connection to the public grid is carried out by you or your specialist partner; the commissioning takes place together with the responsible grid operator.

From Planning to Installation – Substructures for your Project

Reca RS accompanies you comprehensively: from system selection and layout planning to verifiable statics and foundation design. Each solution is individually adapted to the technical and site-specific requirements – including wind and snow loads, soil conditions and approval requirements.

After completion of the planning, we take over manufacturing and logistics. The installation is carried out on request by our own teams – or we support the self-assembly with clear technical documentation.

Ground-mounted PV systems have a tremendous advantage over roof systems. The roof does not always have sufficient area and load-bearing capacity to build a photovoltaic power plant. It also excludes the possibility of later expansion and is difficult to access for maintenance and cleaning work, which is not a problem with ground-mounted systems.

Ground-mounted photovoltaic systems achieve high energy yields. The larger the system, the more economical the project becomes. Ground-mounted systems can be erected and operated on low-yield agricultural land as well as on conversion areas (e.g. former landfills). Solar power can also be generated cost-efficiently with Agri-PV or Floating-PV systems.

When designing the Reca RS mounting systems, we have tried to additionally utilize and emphasize all the essential advantages of the ground-mounted solutions, including their reliability and the possibility of quick and easy installation.

Experienced project developers support investors in the construction of open-field photovoltaic systems. Many actors benefit from intelligently planned solar parks: Regional value creation increases. Builders increase the share of green electricity and contribute to climate protection.

Join the energy transition in the country! We will be happy to advise and support you.

About Reca Solar – Proven Manufacturing, Practical Expertise

Reca Solar is a Poland-based manufacturer of photovoltaic substructures – specializing in open-field systems for projects throughout Europe. Our working method is based on many years of experience in the delivery and installation of PV systems – with a clear focus on the requirements that mounting systems must meet on site.

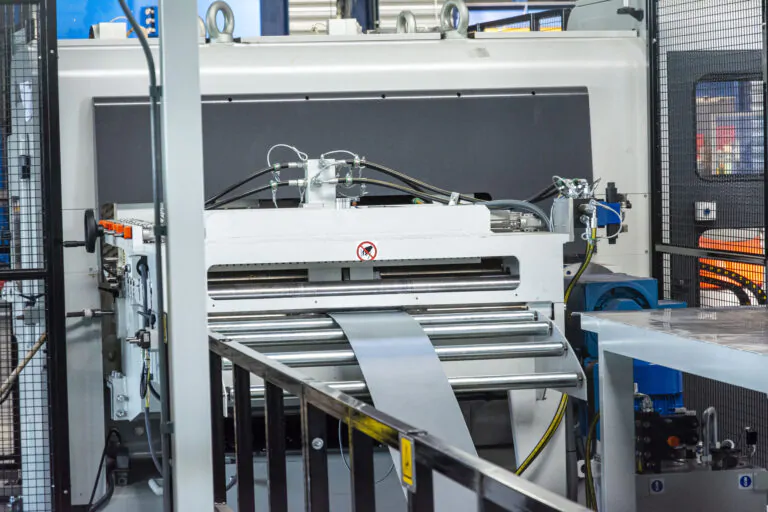

This practical experience shapes our planning and production: Our production facilities are equipped with modern technology and enable scalable series production of steel components with consistent quality.

We value smooth processes, clear schedules and well-thought-out systems – tailored to the real requirements of projects. The close cooperation between our

Advantages of working with Reca RS:

Completed Projects – Open-field PV Systems

The quality of our systems proves itself in use: Reca RS substructures are used in numerous open-field PV systems throughout Europe – with a focus on markets in Germany, Austria and Poland. Our portfolio includes projects of various sizes and technical complexity –

FAQ – Frequently Asked Questions about PV Substructures for Open Spaces

Contact us to start your open-field PV project.

Are you planning an open-field photovoltaic system? Contact us for a personal consultation, detailed planning support, and a non-binding offer. Our team will assist you from the initial idea to the final installation.

Then you can schedule an appointment directly below or request a free indicative offer now – including a recommendation for the appropriate substructure.